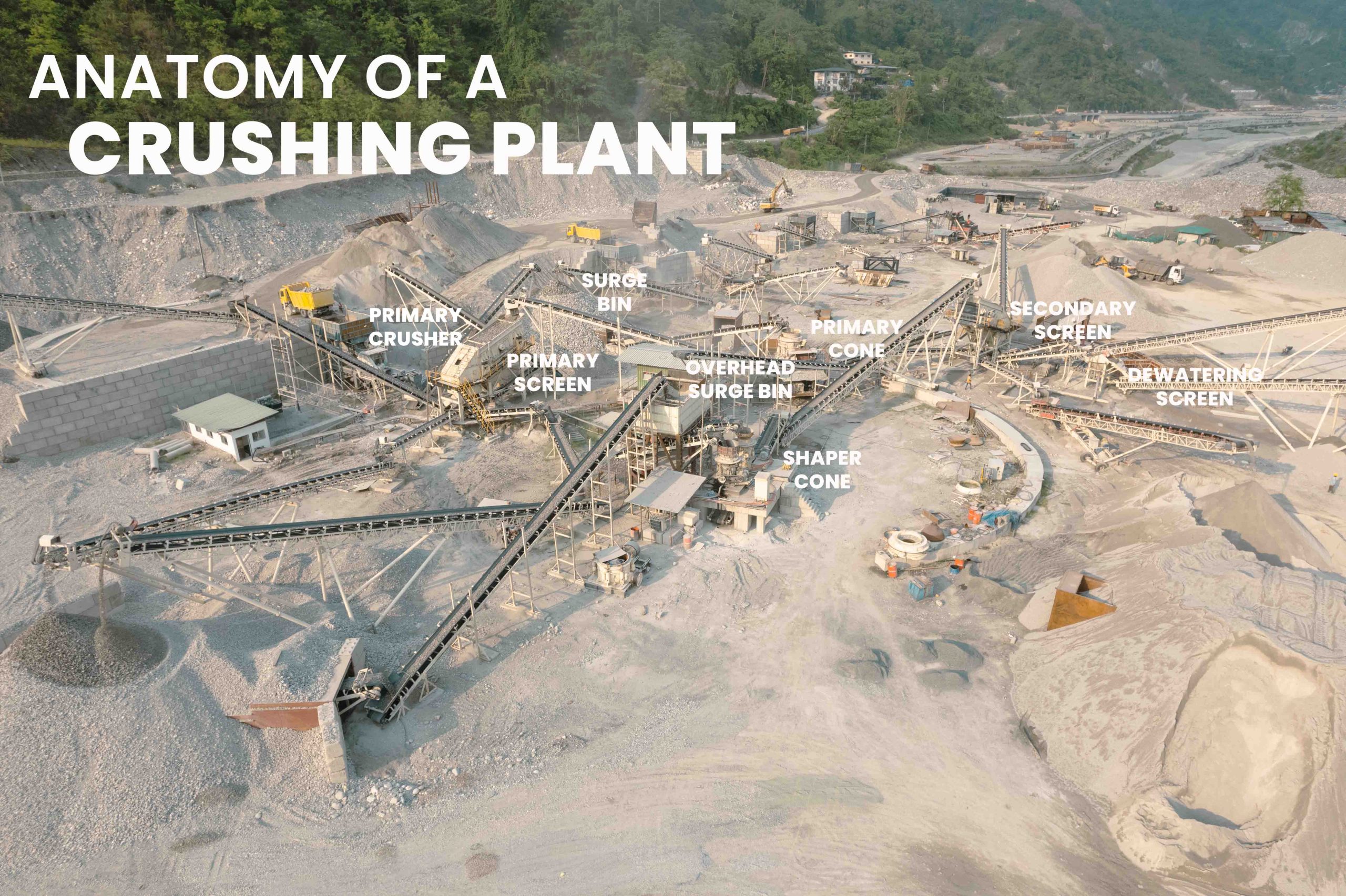

Producing high-quality stone aggregates with low flakiness and elongation involves several key stages in the production process. Here’s a detailed description of each stage, including the use of cone crushers, vibratory screens, VSIs, and washing processes:

Primary Crushing : The process begins with the primary crushing of large stone boulders into smaller sizes. A jaw crusher is commonly used for this purpose, as it can crush the stone into uniform sizes suitable for further processing.

Secondary Crushing and Screening with Vibratory Screen: The crushed stone from the jaw is further processed by reducing its size; it is then screened to separate the different sizes of aggregates. A vibratory screen is used for this stage, which efficiently separates the aggregates based on size. This helps ensure that the final product has a consistent size distribution.

Shaping Stage: To achieve the desired shape and reduce flakiness and elongation, the aggregate is further processed using a shaper cone or a VSI crusher. The chamber of the cone is specifically designed in order to produce the best shape of the aggregates, leading to reduction in flakiness.

Washing Process: Washing the aggregates is crucial to remove any remaining dust, clay, or other impurities. This is done using a washing process, where the aggregates are mixed with water and then passed through a series of screens and classifiers to remove the impurities. The washed aggregates are then dried to remove excess moisture.

Final Screening: After washing, the aggregates are screened again to ensure that they meet the required specifications for size and shape. Any remaining impurities are removed during this stage, and the final product is clean and ready to be used in construction projects.

By following these stages in the production process, it is possible to produce high-quality stone aggregates with low flakiness and elongation, ensuring that they meet the stringent requirements of construction projects.